威元电子

WELLYANG Electronics

公司简介

联系我们

东莞市威元电子科技有限公司

东莞市威元电子科技有限公司是一家生产提供变压器及其它电子线圈制造的专业设备供应商。

公司一直致力于全自动系列设备的研究,主要设备有:全自动平面口罩机、全自动绕线机,全自动焊锡机,全自动磁芯组装包胶测试线,全自动高压综合测试线,纸管音圈自动生产线,全自动测试包装生产线,变压器全制程生产线,电感自动化生产线以及非标准自动化系列设备。

公司秉承“专业制造,精益求精”的生产原则,追求设备高精密与高生产效率,同时更注重产品的亲和性与人性化,为客户端提供更优质的设备。

在产品研究方面,除了在原有的稳固基础上不断完美化,更不断的开发多种非标自动化设备,在全自动化设备上,我们拥有媲美日本、欧洲的性能及品质,不断推出更加完善的设备满足市场与客户的需求。

威元公司凭借丰富的经验与浑厚的实力,以精良的品质、合理的价格、完善的服务,深受国内外市场广大客户的好评,产品远销世界数十个国家,更获得多个世界性知名商家的肯定。

工厂地址:

广东省东莞市虎门镇龙眼东六路21巷28号

销售热线:

13650026778(蒋工)

专业提供变压器及其它电子线圈制造的专业设备生产、设计、制造。拥有丰富的行业经验,产品远销世界数十个国家!

专注于全自动系列设备的研究

同品质产品,性价比更高

纵横具有自主品牌绕线机产品,在同等质量的品牌产品中,更具有价格优势。公司可按照客户的要求在约定的时间内交货。

拥有完善的服务体系

7*24小时在线答疑。提供送货,免费安装,调试服务。在江浙地区设有客户服务中心,为您提供优质、快速的服务!

最新产品

-

-

KF94鱼型口罩机 分类: [ KF94鱼型口罩机 ]

¥0.00¥0.00品牌介绍:

威元电子拥有10多年全自动化研发生产经验,是高精密航空航天自动化技术研发厂商,为美国F35战机提供高精密焊接全自动化设备技术。

公司一直致力于全自动系列设备的研究,主要设备有:全自动平面口罩机、N95口罩机、全自动绕线机、全自动焊锡机、全自动磁芯组装包胶测试线、全自动高压综合测试线、纸管音圈自动生产线、全自动测试包装生产线、变压器全制程生产线、电感自动化生产线以及非标准自动化系列设备。

营销热线:

188 2345 3600(张经理)

137 9849 2961(陈经理)

营销中心:0755-21046194

-

-

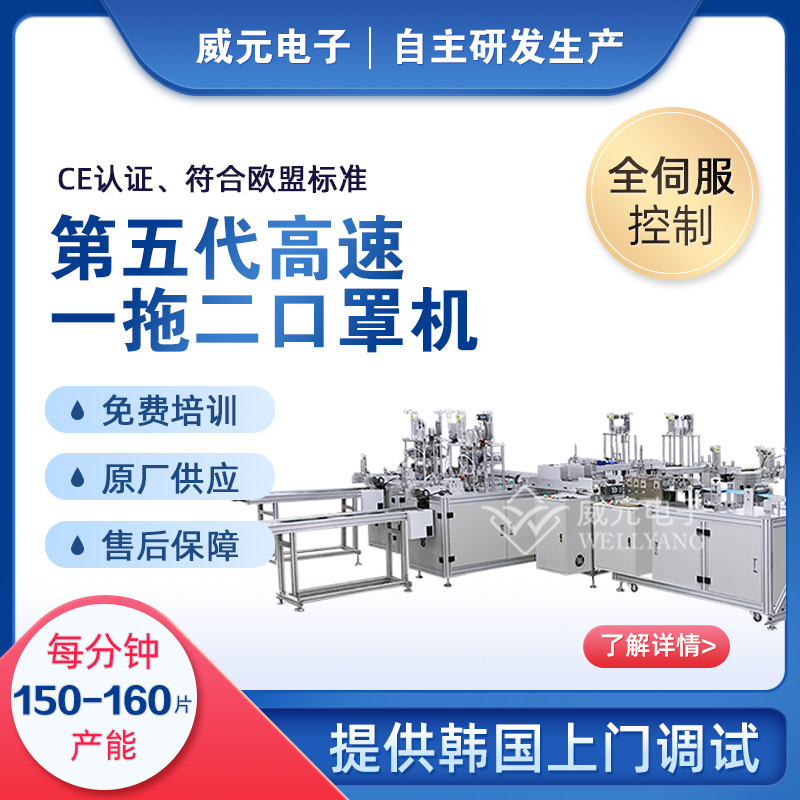

第五代高速一拖二口罩机 分类: [ 全自动平面口罩机 ]

¥0.00¥0.00品牌介绍:

威元电子拥有10多年全自动化研发生产经验,是高精密航空航天自动化技术研发厂商,为美国F35战机提供高精密焊接全自动化设备技术。

公司一直致力于全自动系列设备的研究,主要设备有:全自动平面口罩机、N95口罩机、全自动绕线机、全自动焊锡机、全自动磁芯组装包胶测试线、全自动高压综合测试线、纸管音圈自动生产线、全自动测试包装生产线、变压器全制程生产线、电感自动化生产线以及非标准自动化系列设备。

营销热线:

188 2345 3600(张经理)

137 9849 2961(陈经理)

营销中心:0755-21046194

-

-

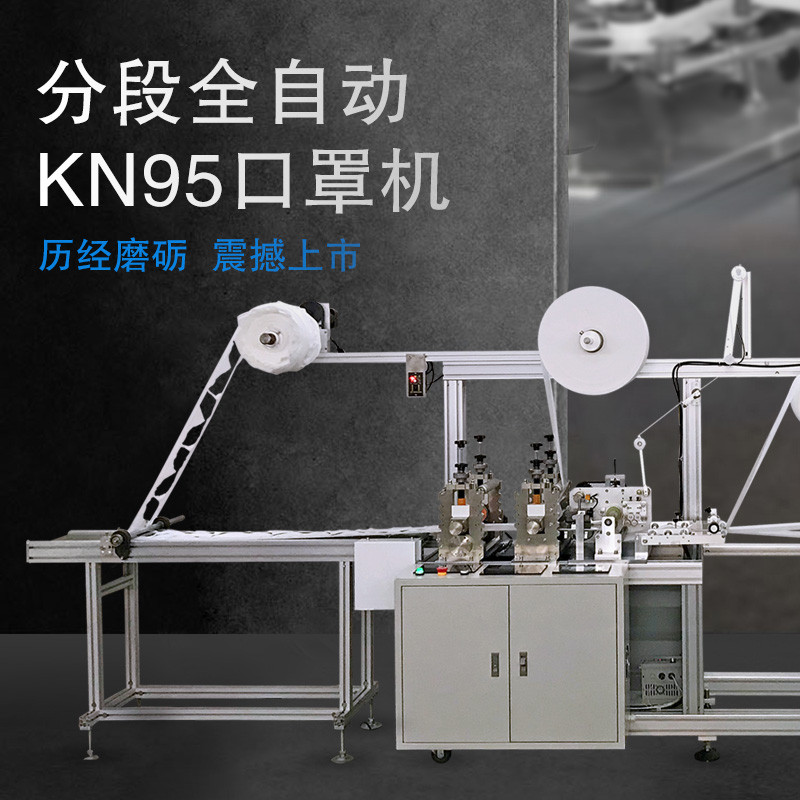

分段全自动KN95口罩机 分类: [ KN95口罩机 ]

¥0.00¥0.00品牌介绍:

威元电子拥有10多年全自动化研发生产经验,是高精密航空航天自动化技术研发厂商,为美国F35战机提供高精密焊接全自动化设备技术。

公司一直致力于全自动系列设备的研究,主要设备有:全自动平面口罩机、N95口罩机、全自动绕线机、全自动焊锡机、全自动磁芯组装包胶测试线、全自动高压综合测试线、纸管音圈自动生产线、全自动测试包装生产线、变压器全制程生产线、电感自动化生产线以及非标准自动化系列设备。

营销热线:

188 2345 3600(张经理)

137 9849 2961(陈经理)

营销中心:0755-21046194